Single-sided, high end rotary tablet press for fast change over between between mono- and bi-layer tablet mode and for high-speed effervescent tablet production.

33 to 71 press stations for max. 511,200 tablets/hour in mono- and bi-layer configuration

Cool – fast – clean tablet compression

- Designed to maintain the process area below 30 °C – ideal for temperature sensitive products

- Optional 3rd compression station for best tablet quality and production performance in mono- and bi-layer production – ideal for effervescent tablet production

- Minimal product loss

- Minimal cleaning effort due to few product contact parts

- No cross-contamination due to hermetical separation between compaction and service area

- Excellent performance with challenging high voume products such as Metformin and Amlodipine

- Special compression rollers, bolts and bearing =s to ensure lowest friction

- Efficient cooling of the torque drive and the V-ring seal for the die table

- No conversion of compression stations required for changing the machine configuration

- Quick product and format changes: tablet chute and fill shoe can be swung out – no tedious readjustments

- 2 full-size shoes

- Patented closed punch bellows to prevent tablet contamination

KeyFeatures

Functionalities

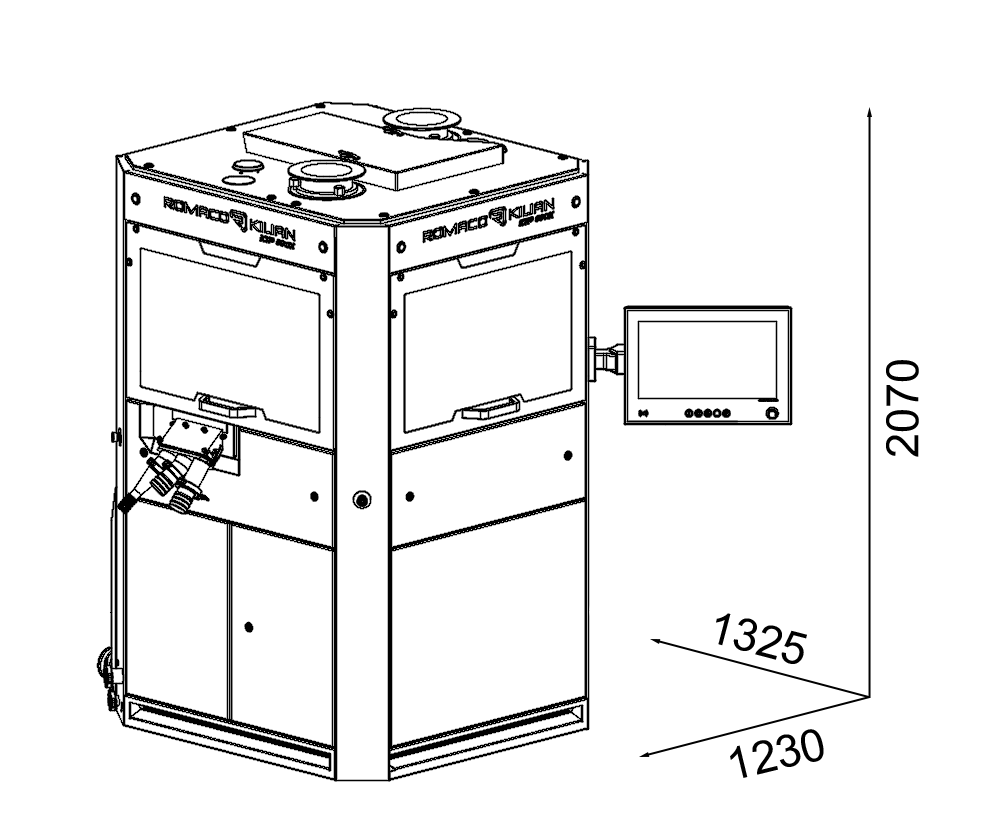

Machine Layout

Datasheet pdf :

Brochure :