Mid-sized, single-sided high end rotary tablet press for pharmaceutical mono-layer applications – impresses with high availability as well as quick and easy format changes.

22 to 50 press stations for max. 360,000 tablets/hour

Cool – fast – clean tablet compression

- Designed to maintain the process area below 30 °C – ideal for temperature sensitive products

- Excellent performance with challenging high volume products such as Metformin and Amlodipine

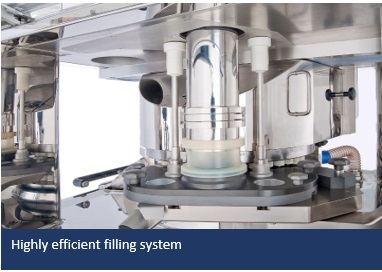

- Minimal product loss

- Minimal cleaning effort due to few product contact parts

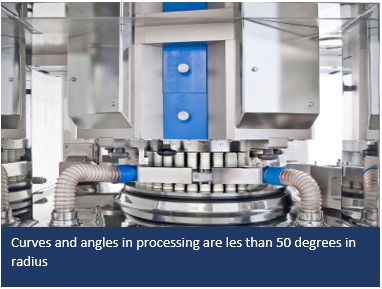

- No cross-contamination due to hermetical separation between compaction and service area

- Special compression rollers, bolts and bearings to ensure lowest friction

- Efficient cooling of the torque drive and the V-ring seal for the die table

- Quick product and format changes: tablet chute and fill shoe can be swung out – no tedious readjustments

- Patented closed punch bellows to prevent black spotted tablets

Key Features

Functionalities

Machine Layout

Datasheet:

Technical Data

| Machine configurations | Mono-layer | ||||

| Number of press stations | 22 | 30 | 37 | 45 | 50 |

| Tool type* (EU and TSM) | KILIAN 35/45 | D | B | B | B |

| Die type | KILIAN 52/30 | D | B | BB | BBS |

| Maximum tablet diameter (mm) | 33 | 24 | 16 | 13 | 11 |

| Maximum output** (tablets/hour) | 79,200 | 198,000 | 266,000 | 324,000 | 360,000 |

| Maximum die filling (mm) | 20 | 18 | |||

| Maximum pre-compression force*** (kN) | 100 | 80 | |||

| Maximum main-compression force *** (kN) | 100 | 80 | |||

| Standard voltage (V), frequency (Hz) | 400, 50/60 | ||||

| Compressed air (bar) | 6 | ||||

| Weight (kg) | 3,500 | ||||