Drying, Granulation, Coating and Hot Melt Coating with state-of-the-art technology for fluid bed processing.

3 batches per shift with a filling range from 12 L to 1500 L processable volume

Most sustainable and future-proof processing solution

- Multipurpose – all in one: Fluid bed granulation, drying and particle coating solution with Dr. hc. Herbert Hüttlin’s patented innovations

- Closed, Clean, Fast – dust free pneumatic product flow with integrated conical mills for converting powder to granulated product

- Highest in-process cleaning efficiency – filtration system SEPAJET®

- Scale-up software based on thermodynamics and InnoTech database

- 100% geometrical scale-up

- Droplet engineering solutions

- Reduced water consumption during cleaning

- Minimized manual operation and set up time

Key Features

Functionalities

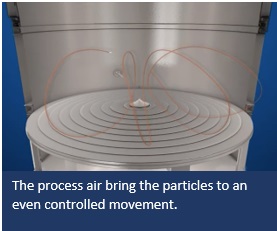

Fluid Bed Dryer with Orbiter

Fluid Bed Granulator with Orbiter & Rotojet

Fluid Bed Granulator Top Spray with Orbiter

Sepajet Dynamic Cleaning

ATEX Certified

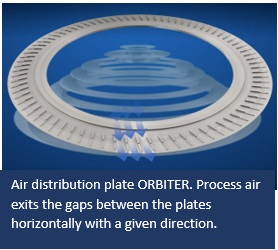

Orbiter Cleanable in Place (CIP)

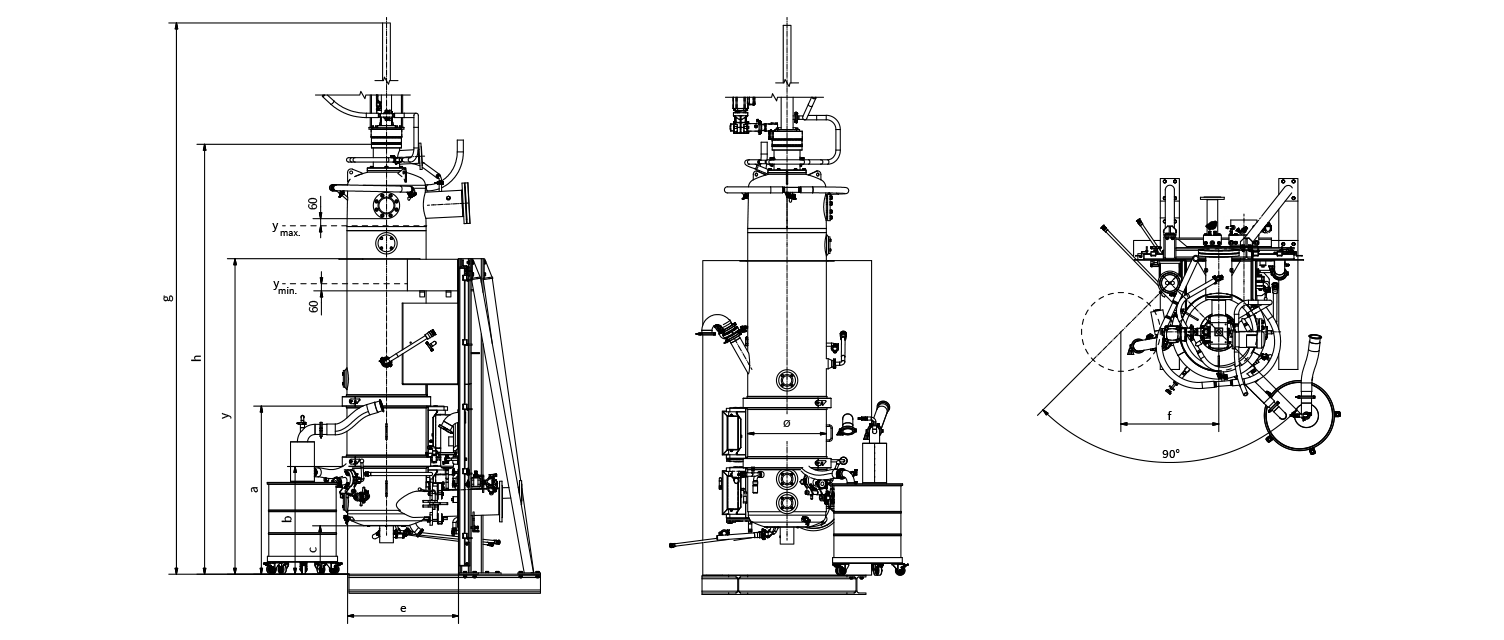

Machine Layout

Technical Data

| Useful Capacity (l) | Dimensions (mm) | ||||

| Model | min. | max. | W | H | L |

| V 75 | 7.5 | 75 | 700 | 2,900 | 700 |

| V 150 | 15 | 150 | 900 | 3,600 | 900 |

| V 300 | 30 | 300 | 1,100 | 4,200 | 1,100 |

| V 450 | 45 | 450 | 1,300 | 4,350 | 1,300 |

| V 600 | 60 | 600 | 1,500 | 4,500 | 1,500 |

| V 900 | 90 | 900 | 1,600 | 4,750 | 1,600 |

| V 1200 | 120 | 1,200 | 1,750 | 5,000 | 1,750 |

| V 1500 | 150 | 1,500 | 1,900 | 5,500 | 1,900 |