Drying, Granulation, Coating and Hot Melt Coating

Equally suited for scale up or for manufacturing small batch sizes

Plug and play – start your GMP manufacturing in seconds …

- GMP compliant design – simple cleanability

- Highest flexibility in batch processing from 4 – 25 litres

- Modern solution as a mobile device or “Through the wall” installation

- The compact design includes the peripheral systems as an all-in-one solution

- Test your business case in real in the market – the pilot is the right solution for this production volumes

- GMP compliant production of clinical samples

- The cylindrical design as used in production machines makes scale up easy and reliable

- Bottom spray with ROTOJET nozzle or top spray

- Hot melt coating processes are possible with the unique Innojet Hot Melt Device (IHD)

- The mobile pilot unit can be installed “plug and play” and fits through a standard door

Functionalities

Orbiter Cleanable in Place (CIP)

Fluid Bed Granulator Top Spray with Orbiter

Fluid Bed Granulator with Orbiter & Rotojet

Fluid Bed Dryer with Orbiter

Sepajet Dynamic Cleaning

Key Features

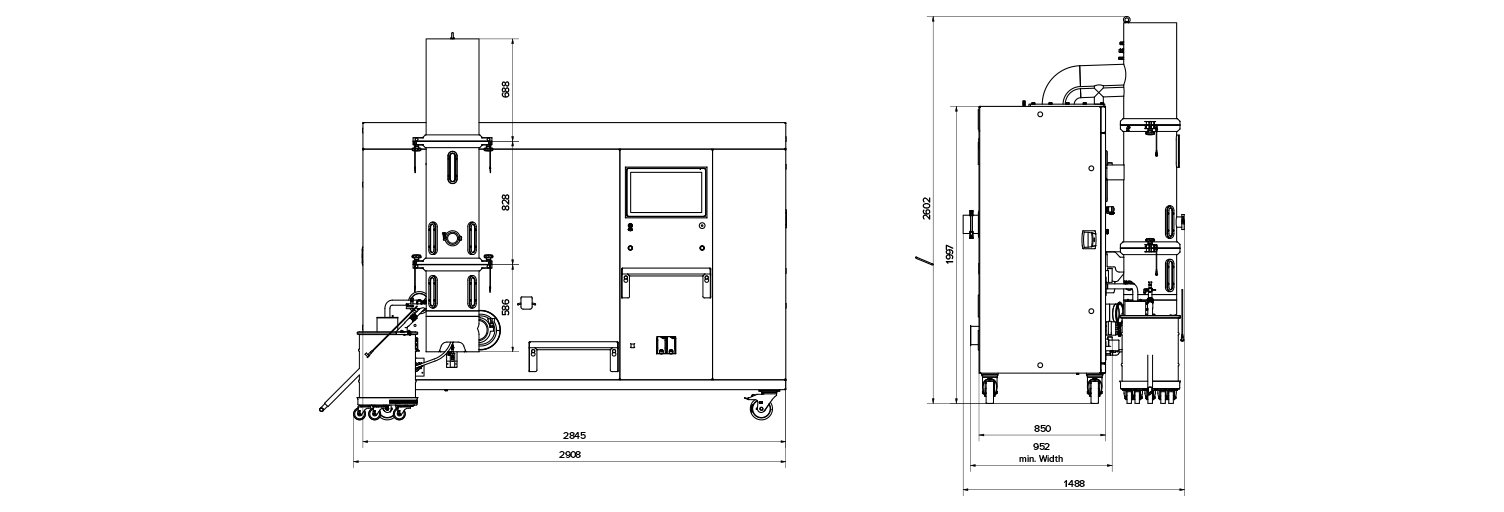

Machine layout

Datasheet Link :

Technical Data

| Max. batch size (kg, at 1g/cm³) | 10 | 25 |

| Min. batch size (kg, at 1g/cm³) | 4 | 10 |

| Product container inside ø = booster ø (mm) | 250 | 350 |

| Inlet air quantity (m³/h) | Max. 500 | Max. 500 |

| Spray air quantity (Nm³/h at 3.0 bar spray pressure) | 20 | 20 |

| Cooling water for dehumidification (glycol-free) (forward/return) (°C) | 6° / 12° | 6° / 13° |

| Power consumption (KW) | Max. 43 | Max. 43 |

| Particle size min. (μm) | 10 | 10 |

| Particle size max. (mm) | 2 | 2 |

| Materials (product-contacted) | Stainless steel AISI 316l – Borosilicate glass Filter media, plastic and seals FDA certified |

|