Standard drum tablet coater. Coating from 40% to 100%. Perforated pan technology allows automatic adjustment of flow, avoiding dampness, saving coating and optimising processing time. Built-in wall supports sustainability.

Batch size from 3.5 L to 900 L

Perforated coating pan for tablets and pellets

- In-wall design concept

- Built in AISI 316L, surfaces in contact with the product are mirror polished with roughness Ra <0.5

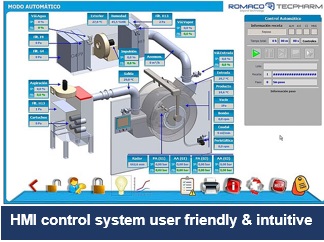

- PLC + Intuitive HMI SIEMENS® for machine control in manual and automatic mode

- Detachable deflectors

- Central transmission with direct coupling

- Schlick spray nozzles

- All speed adjustments by frequency inverter

- Central nozzle arm

- WIP accessories for automatic cleaning

- Spraying control by flow meter

- Air control adjustments fully automatic

- Automatic valves to isolate the process (GMP requirement)

- Sight glass + LED illumination into the drum

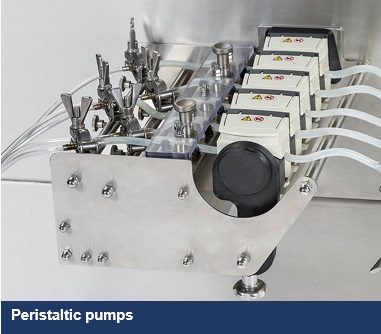

- Peristaltic pump (Watson Marlow) for coating suspension dosage

- Remote connection

Key Features

Functionalities

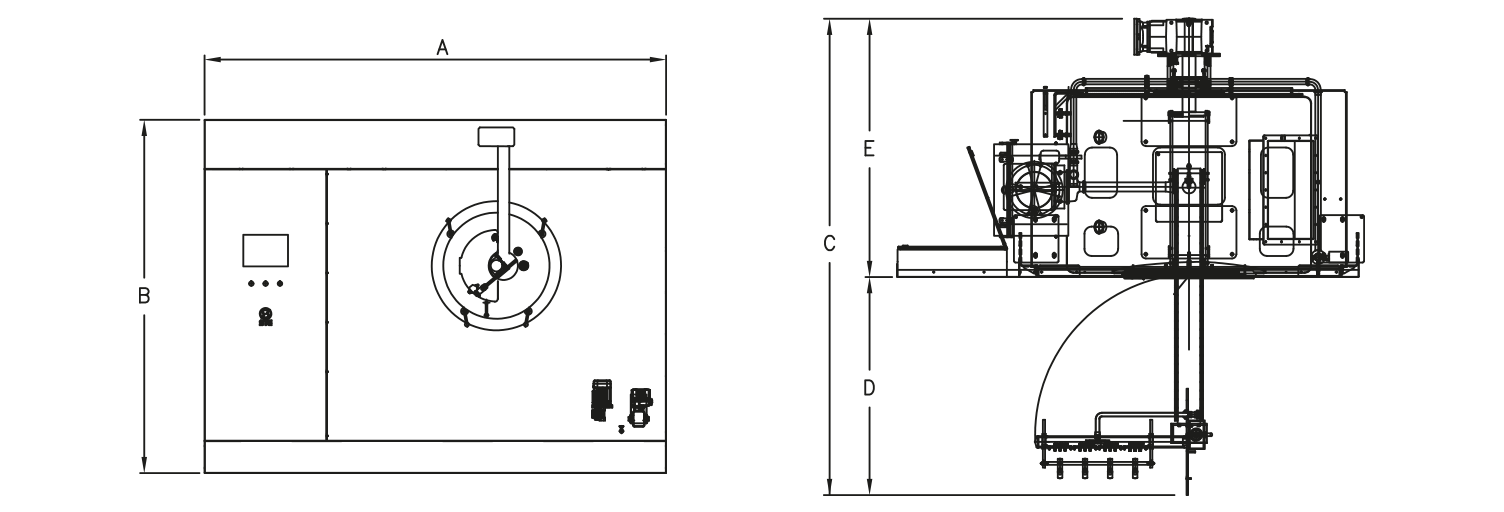

Machine Layout

Technical Data

| Tablet Coaters | Capacity (l) | Dimensions (mm) | |||||

| min. | max. | A | B | C | D | E | |

| TPR i5-10 | 3.5 | 15 | 1,620 | 1,885 | 1,575 | 685 | 890 |

| TPR i50 | 7.5 | 75 | 2,030 | 2,045 | 2,517 | 1,213 | 1,304 |

| TPR 100 | 60 | 150 | 3,210 | 2,254 | 2,838 | 1,300 | 1,538 |

| TPR 150 | 90 | 225 | 3,210 | 2,254 | 3,140 | 1,465 | 1,675 |

| TPR 200 | 120 | 300 | 3,210 | 2,321 | 3,413 | 1,615 | 1,798 |

| TPR 300 | 180 | 450 | 3,510 | 2,542 | 3,975 | 1,845 | 2,130 |

| TPR 400 | 240 | 600 | 3,510 | 2,785 | 4,628 | 2,105 | 2,523 |

| TPR 500 | 300 | 750 | 3,840 | 3,050 | 5,390 | 2,400 | 2,990 |

| TPR 600 | 360 | 900 | 3,840 | 3,340 | 6,275 | 2,730 | 3,545 |

DATASHEET :