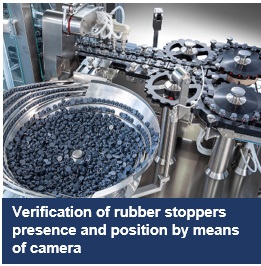

High speed sterile powder filling and stoppering. Double powder dosing station machine with highly ergonomic supply of product components in aseptic environment. Vacuum-pressure technology, integrated check weighing system and rubber stoppering by means of pick and place with verification of cap presence are some of the key features of MicroMaxX Series.

Up to 24,000 vials/hour with a filling range (single shot per dosing disc) of 30 mg to 1,500 mg

Where versatility and fast production meet

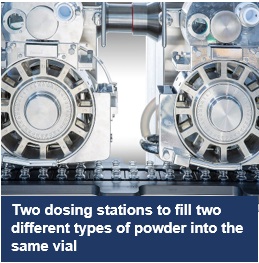

- Up to two different types of powders filled into the same vial

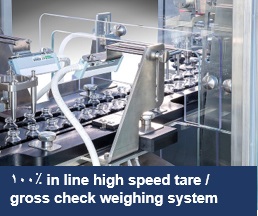

- 100% in line check weighing with feedback to dosing system

- Easy tool-free replacement of product contact parts from machine front side

- Ergonomic handling of components

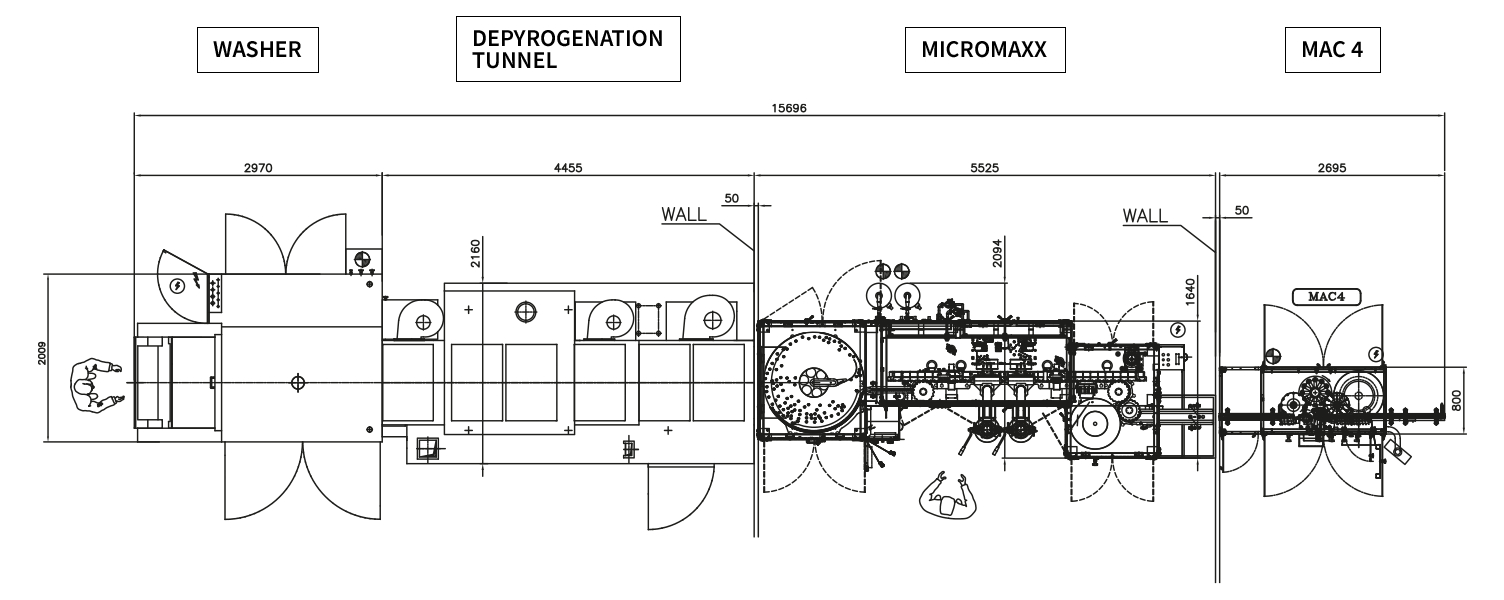

- Compact footprint

- Unique LEV design to minimize powder dispersion in the filling area

- Suitable for oxygen-sensitive products due to system for reducing oxygen level below 3 %

Key Features

Functionalities

Machine Layout

Technical Data

| MicroMaxX 18 | MicroMaxX 24 | |||

| Vials Diameter (mm), min. – max. | 16–52 | 16–32 | 16–52 | 16–32 |

| Vials Height (mm), min. – max. | 35–110 | 35–75 | 35-110 | 35–75 |

| Maximum output (vials/hour)* Single dose per dosing disc, no C.W. |

6,000 | 18,000 | 12,000 | 24,000 |

| Maximum output (vials/hour)* Single dose per dosing disc, 100 % C.W. |

4,000 | 12,000 | 12,000 | 24,000 |

| Dosing range (mg), min. – max. Single shot per dosing disc, dosage can change in relation to powder specific weight |

20–1,500 | |||

| Discs | Two single | Two double | ||

| Dosing chambers per disc | 12 | 12+12 | ||

| Power consumption (kW), without L.F. – with L.F. | 12.7 – 16.7 | |||

| Compressed air for powder ejection (Nl/min), at 7 bar | 120 | |||

| *Depending on product and machine configuration | ||||

DATASHEET :