Non-sterile powder filling and capping. High accuracy filling of non-free flowing powders and dry syrups into glass or plastic bottles. Closing unit can be customized to handle any type of cap.

Up to 8,000 bottles/hour

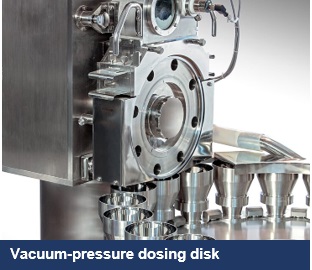

Reliable technology for precise powder filling in non-aseptic operations

- Glass partition wall separating the closing station from the filling station to avoid particle contamination of the bottles

- Individually configurable pistons and stainless steel wire mesh filters according to powder’s physical properties

- Also available without the closing group

- Multiple filling into one bottle to increase the dosing range available upon demad

- No bottle no filling available upon demand

Key Features

Functionalities

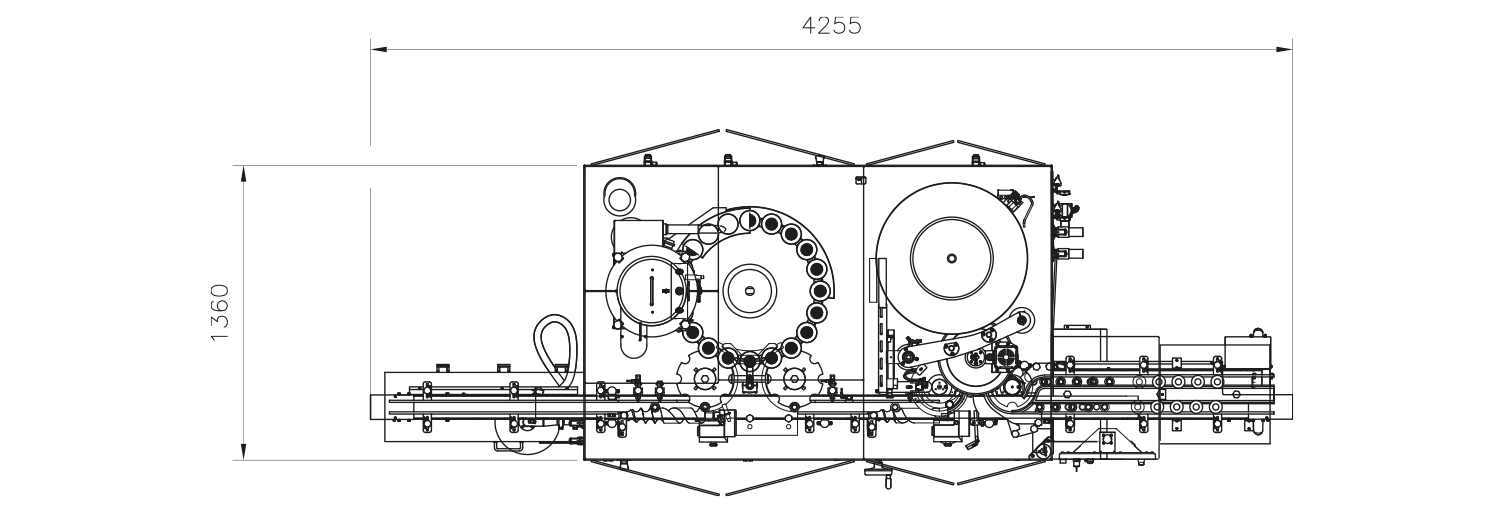

Machine Layout

Technical Data

| MACRO-D 5 | MACRO-D 8 | |

| Format range diameter (mm), min. – max. | 30–60 | |

| Format range height (mm), min. – max. | 50–170 | |

| Mechanical production (pieces/hour), depending on vial stability, powder characteristics and installed options | 5,000 | 8,000 |

| Standard dosing range (cc), min. – max. (single shot) | 6–90 | |

| Installed power (kW), only dosing | 5 | |

| Installed power (kW), with closing unit | 7 | |

| Compressed air consumption (Nl/min.) | 200 | |

| Compressed air pressure (bar) | 7 | |

| Net weight (kg) | 1,700 | 1,950 |

| Gross weight (kg) | 2,200 | 2,700 |

| *Depending on product and machine configuration | ||

DATASHEET :