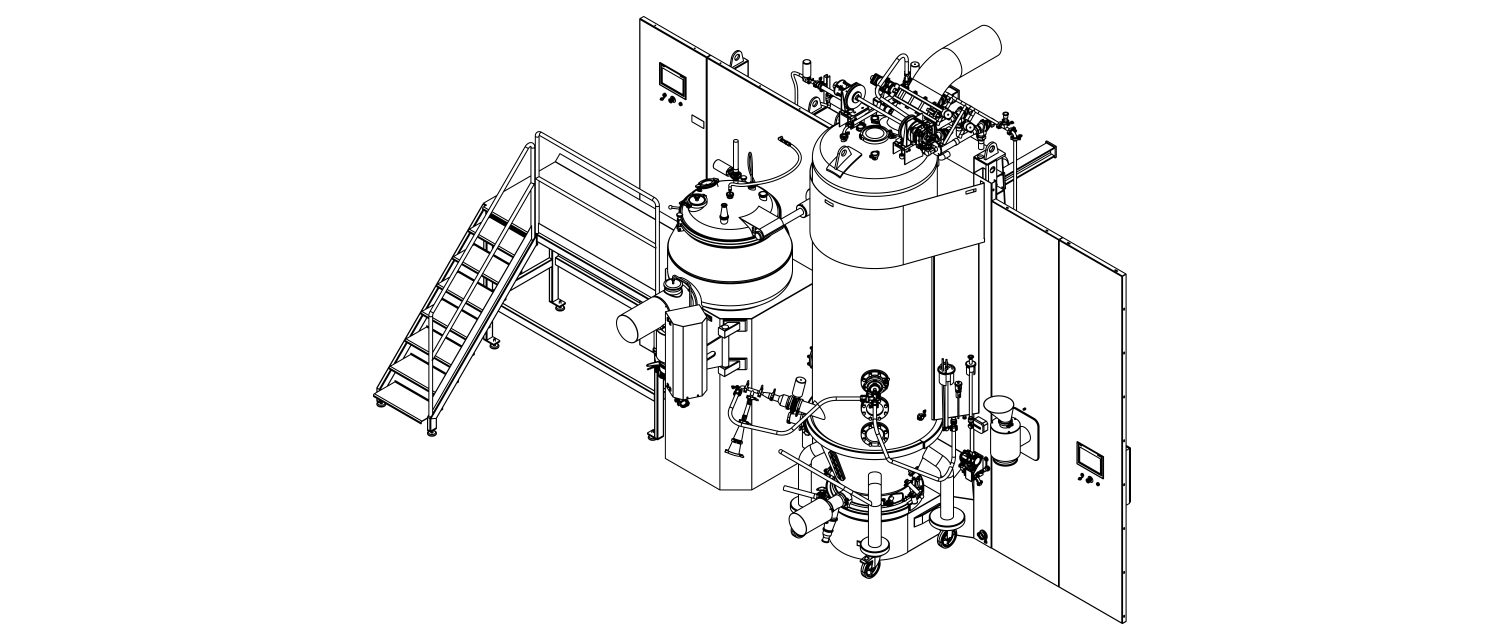

Pharmaceutical granulation line.

Wet granulation process integrated into a single frame.

Maximum versatility for process development

The granulation line integrates all options for the pharmaceutical wet granulation process into a single frame and control panel:

- Mixing and granulation: high shear mixer granulator

- Drying, granulation, coating: fluidised bed dryer

- Calibration: conical and cylindrical calibrators

High Shear Mixer Granulator

- Standard equipment with capacities ranging from 25L to 1400 L other dimensions on request

- In-wall design for integration into clean room

- Manufactured in AISI 316L

- Mirrored polished Ra less than 0.5

- Non-contact top cover without supports in the container

- Bottom impeller and side chopper to ensure intensive mixing in a very short time period

- Control of end point by time or by torque

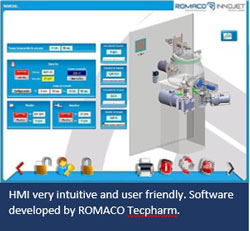

- PLC + HMI for the control in manual and automatic mode, with recipe editing

- Working platform adapted to client’s space (Wurster system)

Fluidized Bed Dryer

Main features

- From 30 L to 1540 L, other dimensions on request

- In-wall desing concept

- Built in AISI 316L, mirror polished Ra less than 0.5

- PCL + HMI in manual and automatic mode, with recipe editing

- 12 bar pressure shock resistance

- Innojet offers a wide range of services: installation “turnkey concept” at the client facilities, start-up, qualification, training, and production support.

Key Features

Functionalities

Fluid bed dryer with sieve bottom plate

High shear mixer granulator

ATEX Certified

Fluid bed coater with Wurster

Fluid bed granulator top spray

Machine Layout