The granulation lines in the IGL series offer high shear mixing with integrated Ventilus® fluid bed processing and shortest process times by means of rapid batch technology.

Several batches per shift with a filling range from 12 L to 1,600 L processable volume

Most sustainable and future-proof processing solution

• Multipurpose – all in one: wet granulation drying and particle coating solution with Dr. hc. Herbert Hüttlin’s patented innovations

• Closed, Clean, Fast – dust free pneumatic product flow with integrated conical mills for converting powder to granulated product

• Integrated gravimetric transfer of granules

Key Features

Functionalities

Fluid bed granulator with orbiter

Controlled product movement

Fluid bed top spray with orbiter technology

Wet transfer

Impactor blade

ATEX Certified

Sepajet

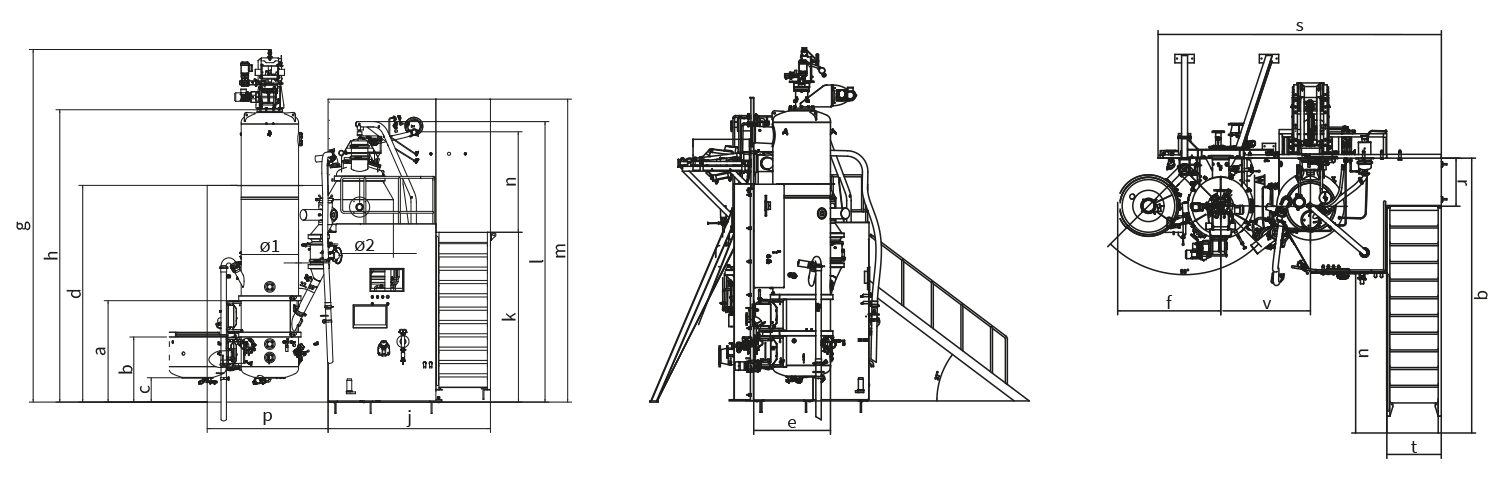

Machine layout

Datasheet :

Technical Data

| Model | min. | max. | W | H | L |

| IGL 75 | 20 | 60 | 1,720 | 2,700 | 1,840 |

| IGL 150 | 40 | 120 | 4,400 | 4,400 | 4,400 |

| IGL 300 | 75 | 240 | 4,425 | 4,400 | 4,470 |

| IGL 450 | 110 | 360 | 5,360 | 5,000 | 4,550 |

| IGL 600 | 150 | 480 | 5,490 | 5,000 | 4,550 |

| IGL 900 | 225 | 720 | 5,766 | 5,000 | 4,600 |

| IGL 1200 | 300 | 960 | 6,260 | 5,000 | 4,600 |

| IGL 1500 | 375 | 1,200 | 6,270 | 5,000 | 4,800 |