Traditional drying, granulation and coating: the best solution for drying a wide range of products, especially in the pharmaceutical industry.

Performance: 8 L to 1,232 L

Designed to perform 3 different processes:

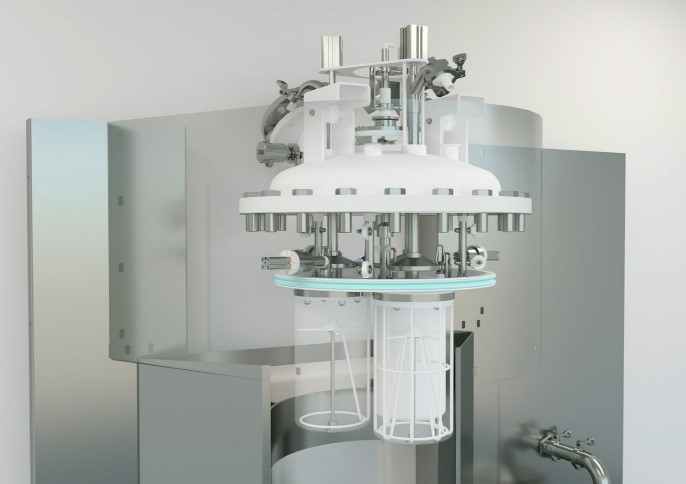

1. Drying of wet granulate (dryer)

2. Granulation by top spraying (granulator)

3. Coating by bottom or tangential spraying (coater)

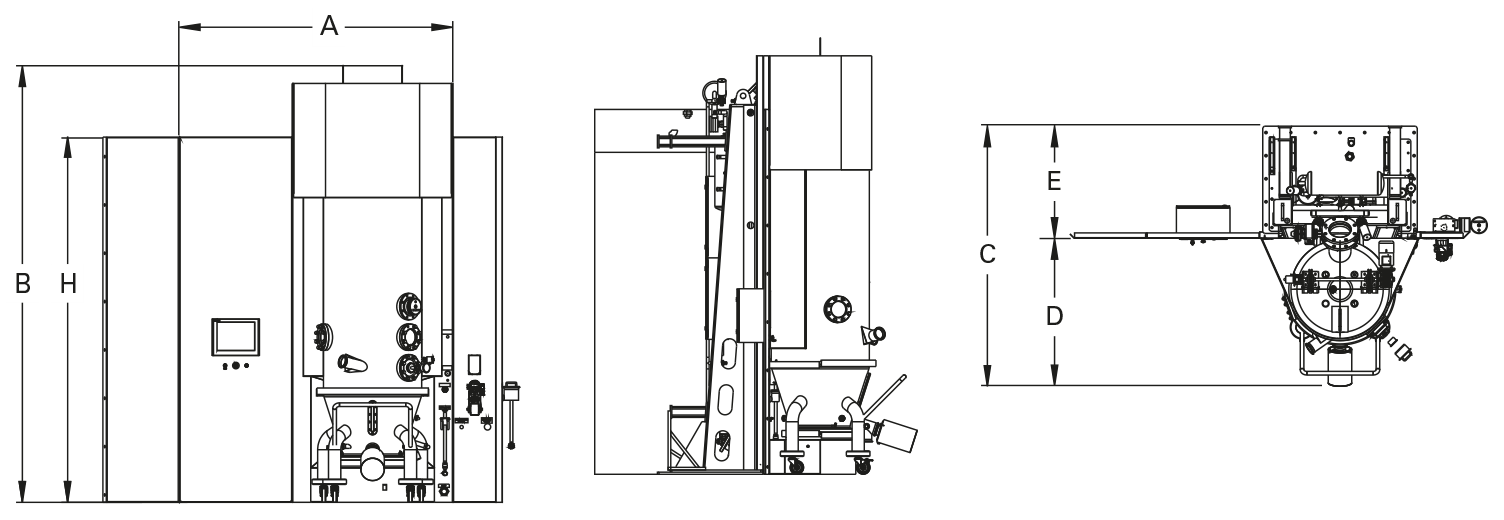

4. From 30 L to 1540 L , other dimensions on request

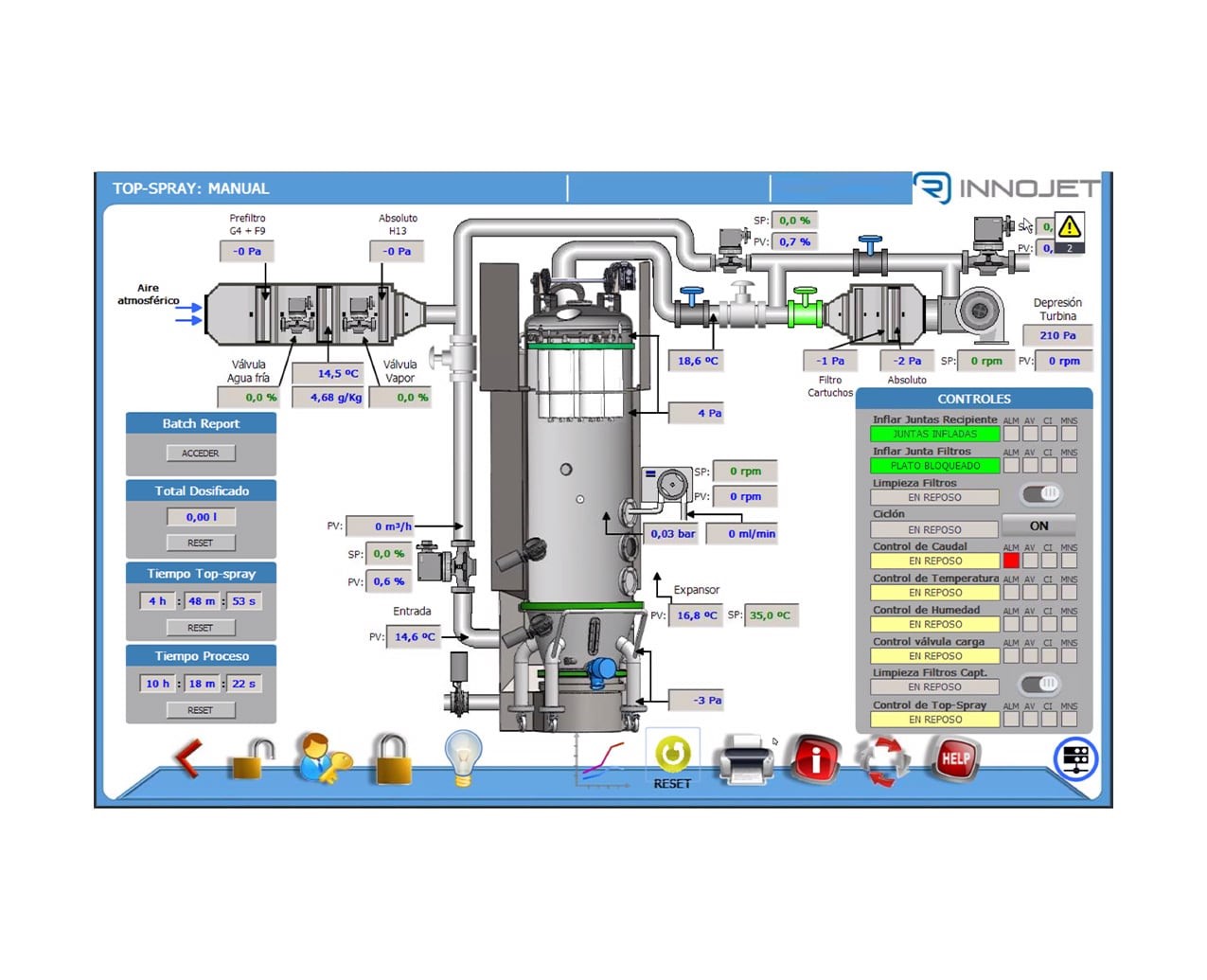

5. In-wall design concept

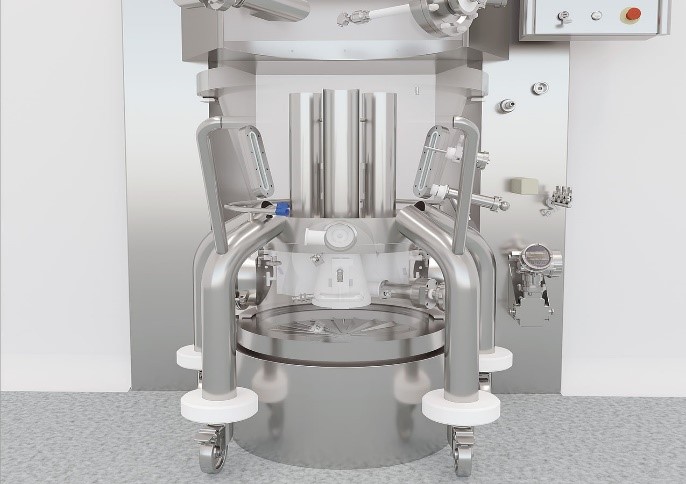

6. Built in AISI 316L, mirror polished Ra less than 0.5

7. PCL + HMI in manual and automatic mode, with recipe editing

8. 12 bar pressure shock resistance

Technical Data

| Model | Min | max | A | B | C | D | E |

| IFT 30 | 6 | 24 | 2000 | 2650 | 1650 | 950 | 2500 |

| IFT 60 | 12 | 48 | 2075 | 3250 | 2100 | 1150 | 3000 |

| IFT 100 | 20 | 80 | 2250 | 3600 | 2250 | 1250 | 3200 |

| IFT 200 | 40 | 160 | 2300 | 3900 | 2450 | 1400 | 3400 |

| IFT 300 | 60 | 240 | 2450 | 4350 | 2550 | 1500 | 3500 |

| IFT 400 | 80 | 320 | 2600 | 4750 | 2650 | 1600 | 3600 |

| IFT 600 | 120 | 480 | 2800 | 5250 | 3050 | 1800 | 3800 |

| IFT 800 | 160 | 640 | 3000 | 5800 | 3250 | 2000 | 3900 |

| IFT 1000 | 200 | 800 | 3100 | 6357 | 3650 | 2107 | 4000 |

| IFT 1300 | 260 | 1040 | 3200 | 6475 | 3900 | 2250 | 4000 |

| IFT 1500 | 300 | 1200 | 3350 | 6000 | 4250 | 2400 | 4500 |

Datasheet : https://www.romaco.com/files/user_upload/Romaco_Innojet_ITF_FluidBed_Landscape.pdf