Sterile liquid filling lines. MACOFAR E includes a series of washers, depyrogenation tunnels and liquid filling machines to configure the perfect aseptic liquid filling line for vials intended for injection.

Up to 24,000 vials/hour

Quality – budget – schedule on point

- Sterile liquid filling turnkey solution up to external decontamination machine

- Selection of preset configurations for sterile liquid filling matching the needs of the pharmaceutical industry

- Cost-effective solution

- 100 % tare/gross check weighing system with automatic filling adjustment

- Zero loss logic end-of-batch procedure

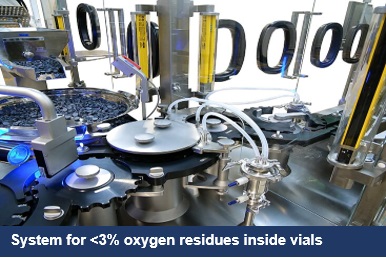

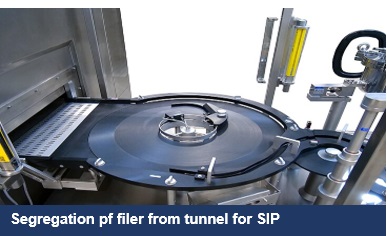

Key Features

Functionalities

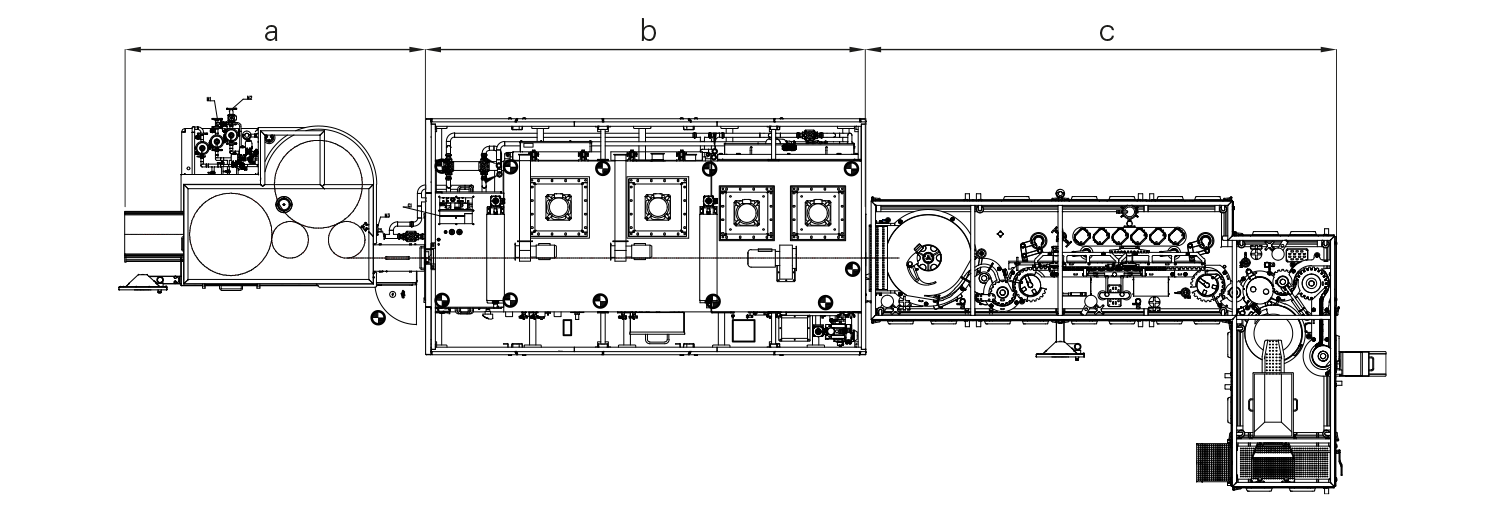

Machine Layout

Technical Data

| Aseptic Liquid Filling | ||||

| Maximum speed (vials/hour), based on 10R-2ml filling volume |

Washer – a (mm) | Depyrogenation tunnel – b (mm) | Filler – c (mm) | Utilities (Power / Water / Compressed air) |

| 6,000 | MRW 12/2 – 2,840 | MDT 422 – 3,620 | MVF 100 – 3,850 | Installed power 90 kW; 400 L/h 3 bar WFI; 30 Nmq/h 6 bar CA |

| 12,000 | MRW 12/4 – 2,840 | MDT 622 – 3,820 | MVF 200 – 4,300 | Installed power 125 kW; 600 L/h 3 bar WFI; 45 Nmq/h 6 bar CA |

| 24,000 | MRW 20/5 – 3,260 | MDT 944 – 4,550 | MVF 400 – 5,400 | Installed power 225 kW; 1200 L/h 3 bar WFI; 90 Nmq/h 6 bar CA |