Efficient solution for filling of non-aseptic pharmaceutical and nutraceutical liquid products into a wide range of glass and plastic bottles. The machines can be equipped with up to three capping stations plus a straw/cannula feeding unit.

Up to 15,000 bottles/hour

High speed and versatility for non-aseptic liquid filling

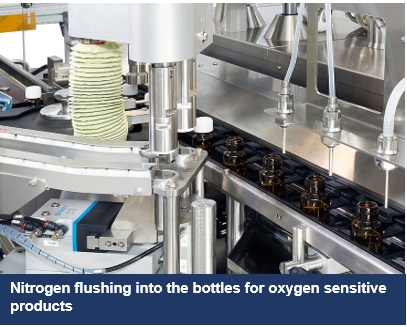

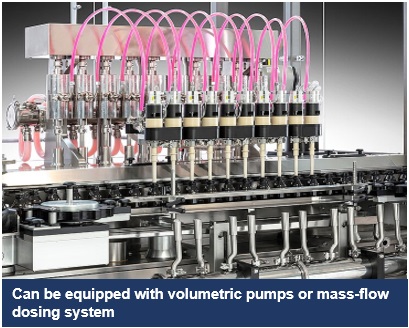

- From sugary, highly viscous products, such as syrups, to alcohol-based, low viscosity products, within the same machine configuration

- Multiple caps handling – screw caps, child-proof caps, droppers, spray pumps, measuring caps and more

- Reliable solution for continuous production of big batches

Key Features

Functionalities

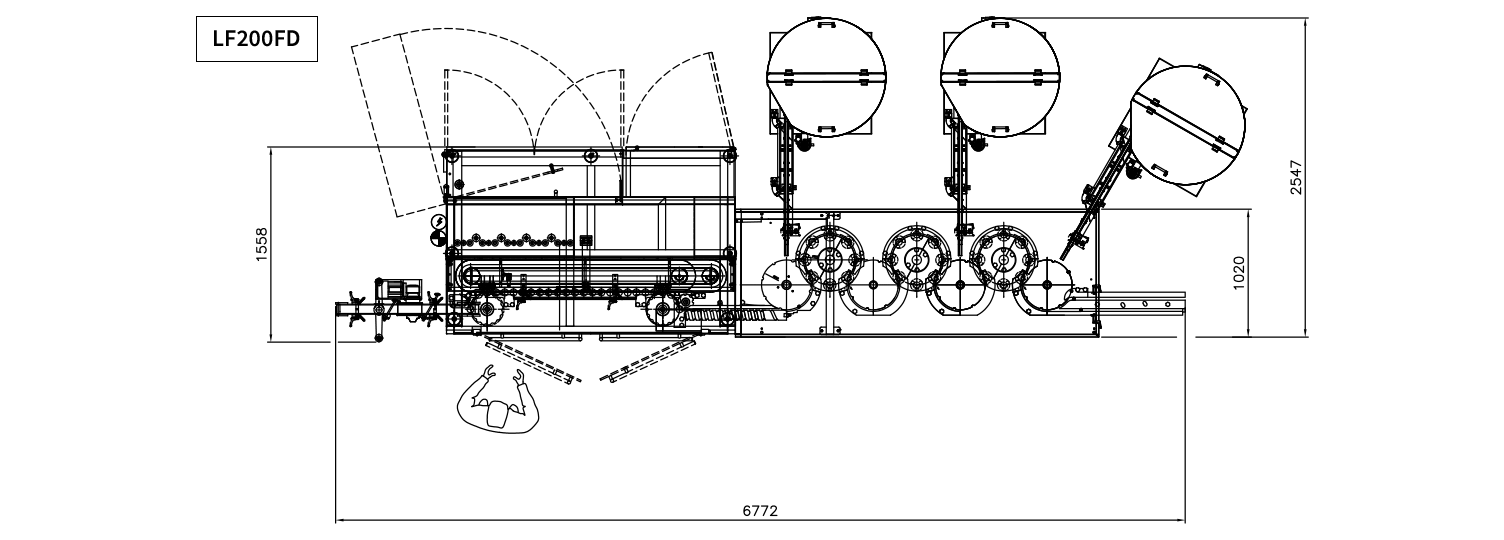

Machine Layout

Technical Data

| LF 150 | LF 200 | LF 250 | |

| Mechanical output (pieces/hour) | 9,000 | 12,000 | 15,000 |

| Fill range (cc.) | 25 ÷ 450 | 5 ÷ 250 | 5 ÷ 70 |

| Vial range diameter (mm) | min. 25 – max. 80 | min. 20 – max. 80 | min. 20 – max. 38 |

| Vial range height (mm) | min. 40 – max. 180 | ||

| Rated Power (kW) | 12.6 | ||

| Compressed air consumption (Nl/min.) | 200 | ||

| PLC | SCHNEIDER | ||

| *Depending on product and machine configuration | |||

DATASHEET :