The fastest and most accurate rotary tablet press for tab-in-tab production and dry-coating.

30 to 50 press stations for max. 140,000 tablets/hour

Precise – fast – clean tablet compression

- Easy set-up and core position control via camera system

- Fast tab-in-tab production

- Low cleaning effort due to few products contact parts

- Minimal product loss

- No cross-contamination due to effective separation between processing and maintenance area

Key Features

Functionalities

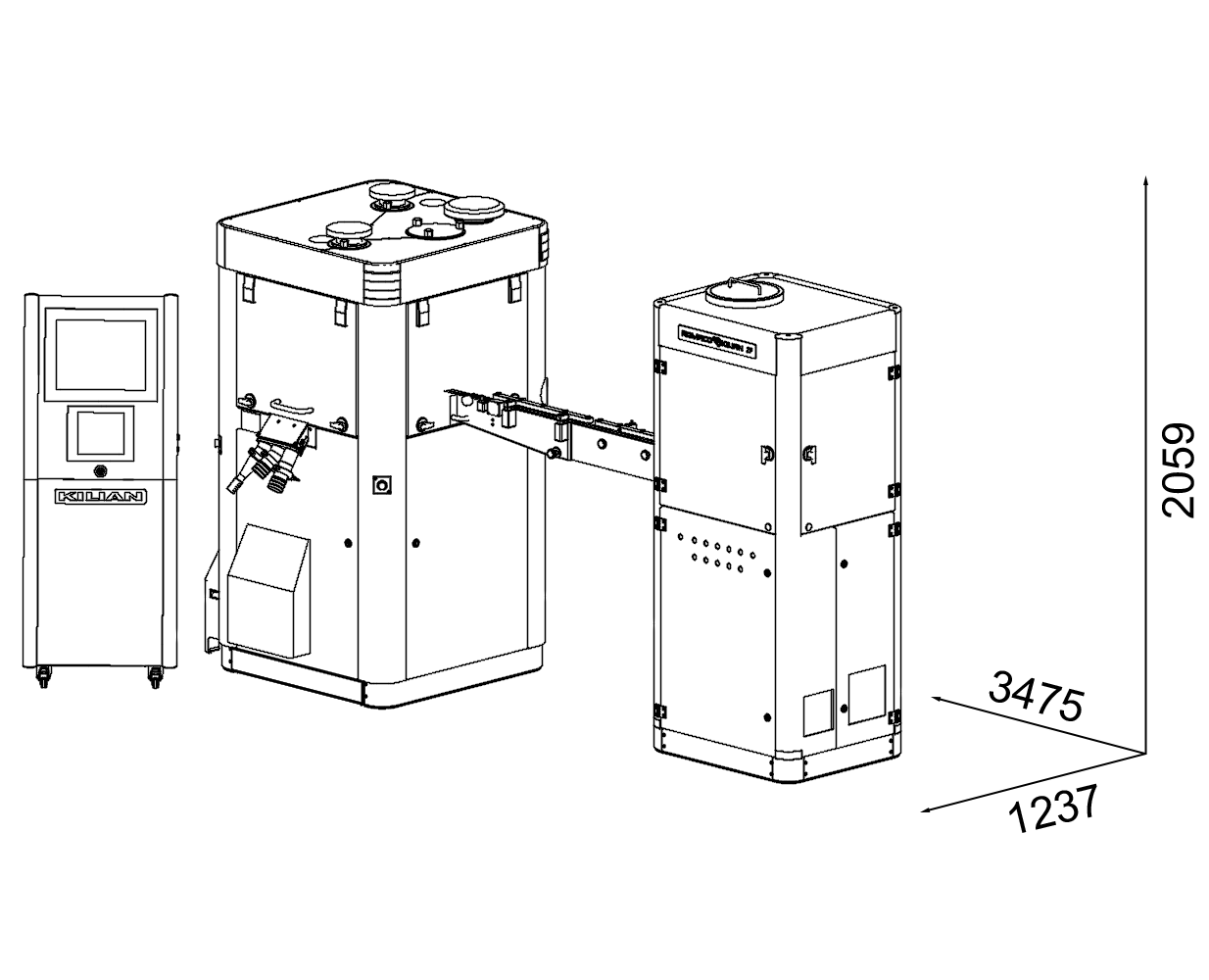

Machine Layout

DATASHEE

Technical Data

| Machine configurations | Tab-in-tab | |||

| Number of press stations | 30 | 35 | 45 | 50 |

| Tool type* (EU and TSM) | D | B | B | B |

| Die type | D | B | BB | BBS |

| Maximum tablet diameter (mm) | 24 | 16 | 13 | 11 |

| Maximum output TT version** (tablets/hour) | 45,000 | 52,500 | 67,500 | 75,000 |

| Maximum output TTH version** (tablets/hour) | 84,000 | 98,000 | 126,000 | 140,000 |

| Maximum die filling first layer(mm) | 20 | 18 | ||

| Maximum punch penetration second layer (mm) | 9 | |||

| Maximum compression force first layer (kN) | 10 | |||

| Maximum compression force second layer*** (kN) | 100 | 80 | ||

| Standard voltage (V), frequency (Hz) | 400, 50/60 | |||

| Compressed air (bar) | 6 | |||

| Weight (kg) | 3,580 | |||