Robotic powder/liquid filling machine for small batches under isolation technology. The MicroRobot 50 can be configured for powder and/or liquid filling (combi filling) under isolation technology – even of high potency drugs and extremely difficult to fill powders. Size parts-free robots manage all operations and vials transfer.

Max. 3,000 vials/hour with minimum dosage: 20 mg / 0.5 ml

Innovation and value

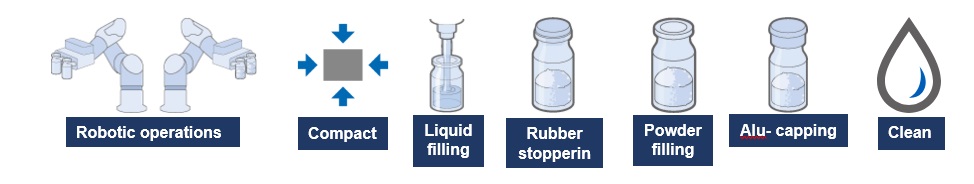

- Format-free robotic transport

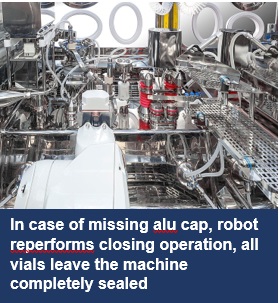

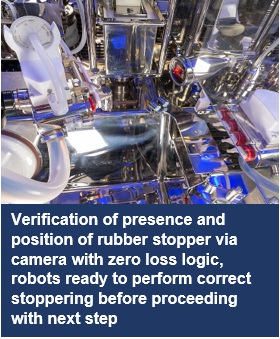

- Zero loss logic for high value products

- Compact design

- Filling, stoppering, and capping all in one machine

- One single machine capable of handling both powder and liquid filling

- Capable of handling oxygen-sensitive products due to a system to reduce oxygen level below 3 %

Key Features

Functionalities

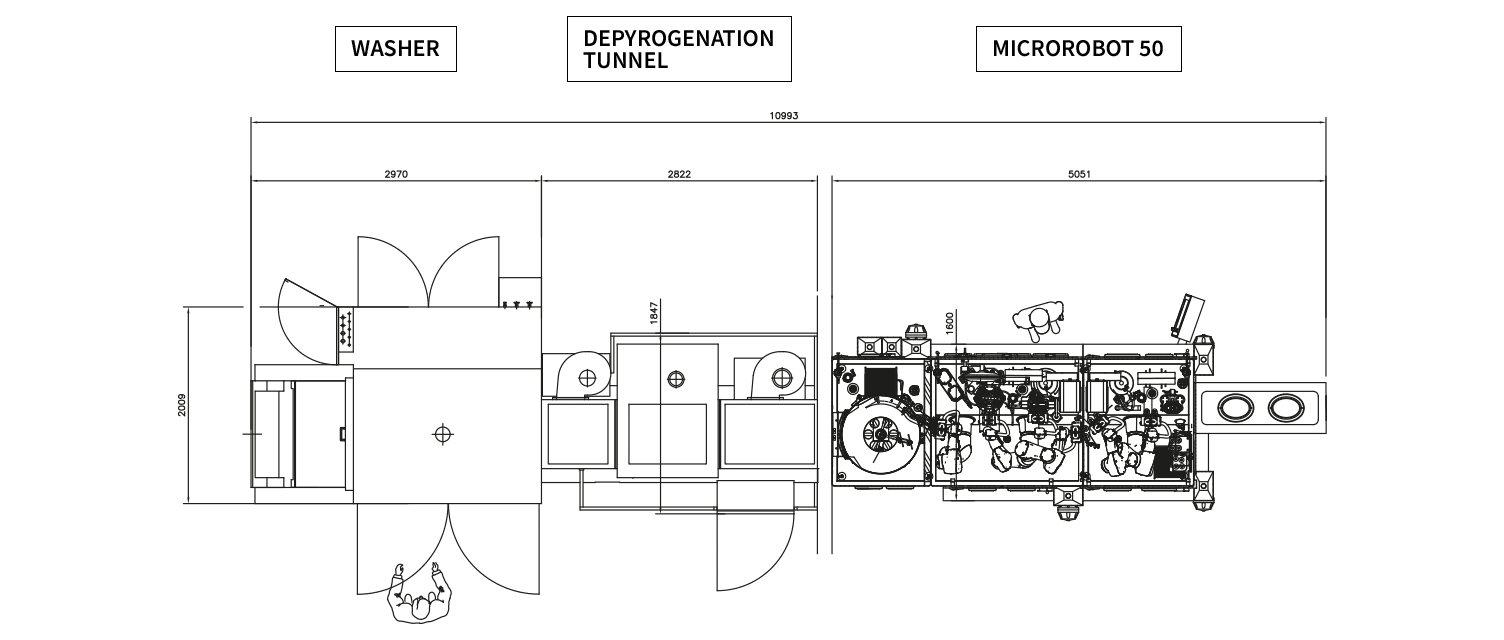

Machine Layout

Technical Data

| Output – single dose (vials/hour) | 3,000 |

| Vial dimensions diameter (mm), min. – max. | 16–52 |

| Vial dimensions height (mm), min. – max. | 35–110 |

| Minimum dose (mg), min. dosages can change according to the powder specific weight | 20 |

| Minimum dose liquid (ml), can vary depending on product’s characteristics | 0.5 |

| Installed power (kW), without L.F. | 22 |

| Compressed air (bar) | 6 |

| PLC standard | SCHNEIDER |

| Machine dimensions (mm), L × W × H | 3,950 × 1,700 × 3,000 |

| Weight (kg) | approx. 6,000 |

| *Depending on product and machine configuration |

DATASHEET :