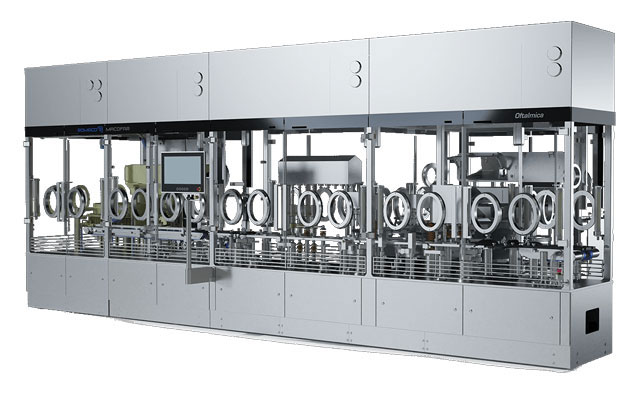

Sterile liquid filling and capping. The Oftalmica machine’s main application is filling and capping of ophthalmic products; additionally, it can easily handle nasal sprays and injectables (small formats).

Max. 12,000 bottle/hour

The art and science of ophthalmic filling

- Minimized change-over parts and downtime due to wide adaptability range of transport system and machine stations

- Dosing system designed according to ophthalmic production needs – capable to maintain high speed/max. output even with viscous and foamy liquids which need to be fed into bottles with small mouths

- Machine designed for aseptic processing according to the latest Annex 1 of cGMP for the manufacturing of sterile medicinal products:

- also suitable for injectable applications

- turnkey solution with washer and tunnel available

- Capping stations can handle all kinds of caps (Aptar, Nemera, Dropper + Screw cap, cannulas, spray pumps and so on)

- All containers can be steadily run – from glass vials to lightweight plastic bottles

Key Features

Functionalities

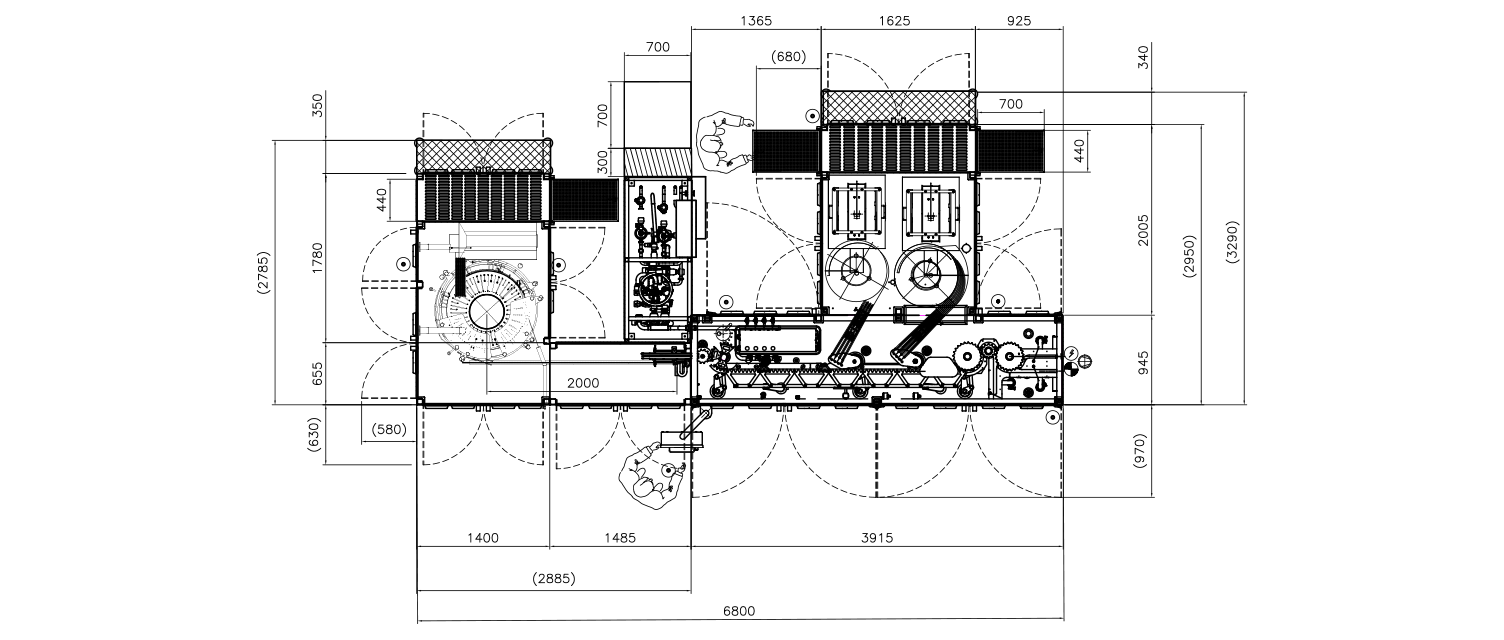

Machine Layout

Technical Data

| OFTALMICA | |

| Output – single dose (vials/hour)* | 12,000 up to 15 ml filling volume |

| Vial dimensions, diameter range (mm) | 16–32 |

| Vial dimensions, height range (mm) | 42–80 |

| Filling range (ml)* | 1–30 |

| Installed power (kW) | 35 |

| Compressed air consumption (NL/min) | 550 |

| PLC standard | Schneider |

| HMI | B&R |

| *Depending on product and machine configuration |