Sterile alu capping of vials. MAC machines are designed for aseptic processes and top-quality sealing of vials.

Up to 24,000 vials/hour

aseptic process

- Alu caps are sealed by moving the vials from below, ensuring the highest quality and preventing scratches or defects

- Secure closing of vials thanks to dedicated idle blade and upper vial contrast, which is optionally equipped with loading cell to continuously monitor sealing force

- Optimised machine layout to avoid contamination from aluminum particles potentially caused by the caps feeding bowl

- Sealing force can be set via machine HMI

Key Features

Functionalities

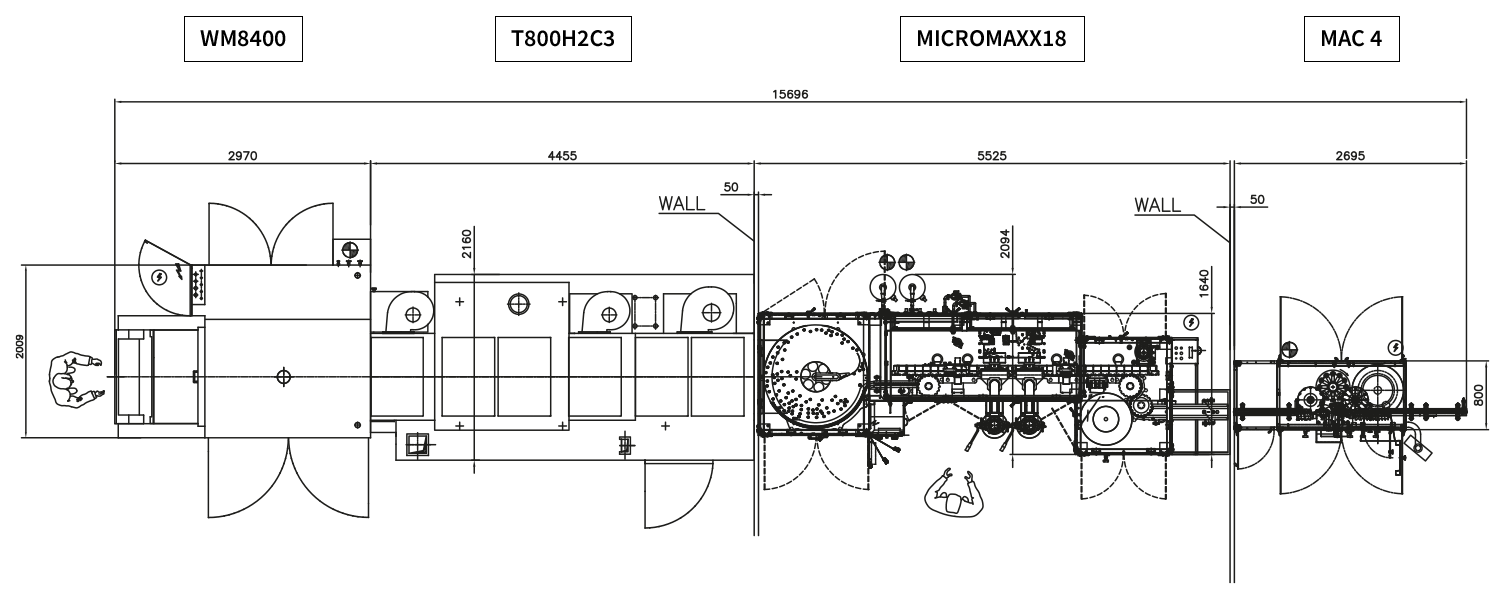

Machine Layout

Technical Data

| MAC 2 | MAC 4 | |

| Vials Diameter (mm), min. – max. | 16–35 | |

| Vials Height (mm), min. – max. | 35–100 | |

| Maximum output (vials/hour)* | 12,000 | 24,000 |

| Closing heads | 2 | 12 |

| Motion | Intermittent | Continuous |

| Rated power (kW) | 2.5 | |

| Weight (kg)* | 800 | |

| PLC | SCHNEIDER | |

| *Depending on product and machine configuration | ||

DATASHEET :