Sterile and non-sterile liquid filling and capping. Compact versatility for complex products: LVI machines can be equipped with different types of liquid filling technologies and capping options. Suitable to handle a wide range of pharmaceutical liquid products. The machine can also be equipped with laminar flow and environmental controls for aseptic processes.

Up to 6,000 bottles/hour

Your little liquid filling all-rounder

- Compact design

- Exceptional versatility:

- wide filling and format range

- can handle injectable, ophthalmic, oral and nasal products

- Multiple capping stations

Key Features

Functionalities

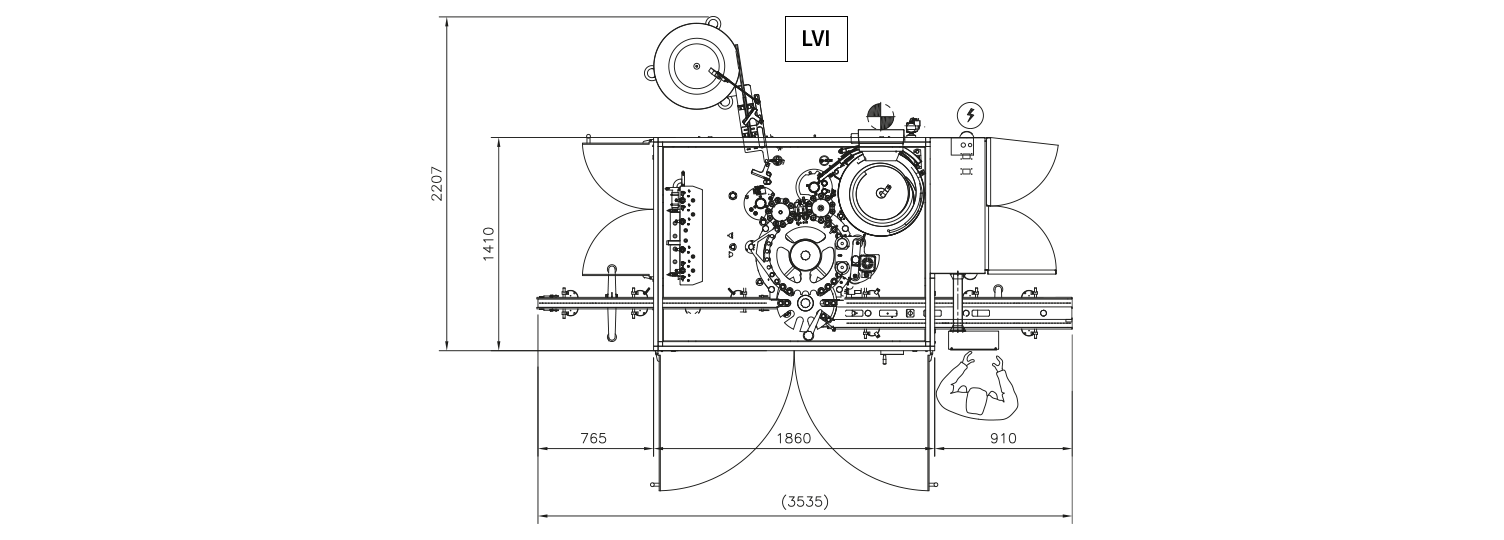

Machine layout

Technical Data

| LVI 4 | LVI 6 | |

| Mechanical output | 4,000 | 6,000 |

| Fill range (cc.) | 1 – 500 | 1 – 100 |

| Vial range diameter (mm) | min. 16 – max. 75 | min. 16 – max. 48 |

| Vial range height (mm) | min. 35 – max. 180 | |

| Rated Power (kW) | 5 | |

| Compressed air (bar) | 6 | |

| Dimensions (mm) | 3,535 × 1,410 × 2,138 | |

| Net weight (kg) | 1500 | |

| Air consumption (Nl/min.) | 200 | |

| PLC | SIEMENS | |

| *Depending on product and machine configuration | ||

DATASHEET :