Romaco platform for track & trace solutions. PTT machines can integrate various carton coding systems as well as labelling systems for tamper evidence on carton flaps and for vignette on top of the cartons. All operations are controlled by the vision system you select. PTT machines can be installed downstream of any cartoner or checkweigher.

Up to 400 cartons/minute

Tracking safety, tracing value

• Compact footprint, suitable for integration into existing production lines

• All operations can be performed from operator’s side

• Flexibility to install any kind of vision system and integrate serialization software or to use a Romaco Vision System partner for a turnkey solution

• Suitable to integrate your printer of choice for carton coding

Key Features

Functionalities

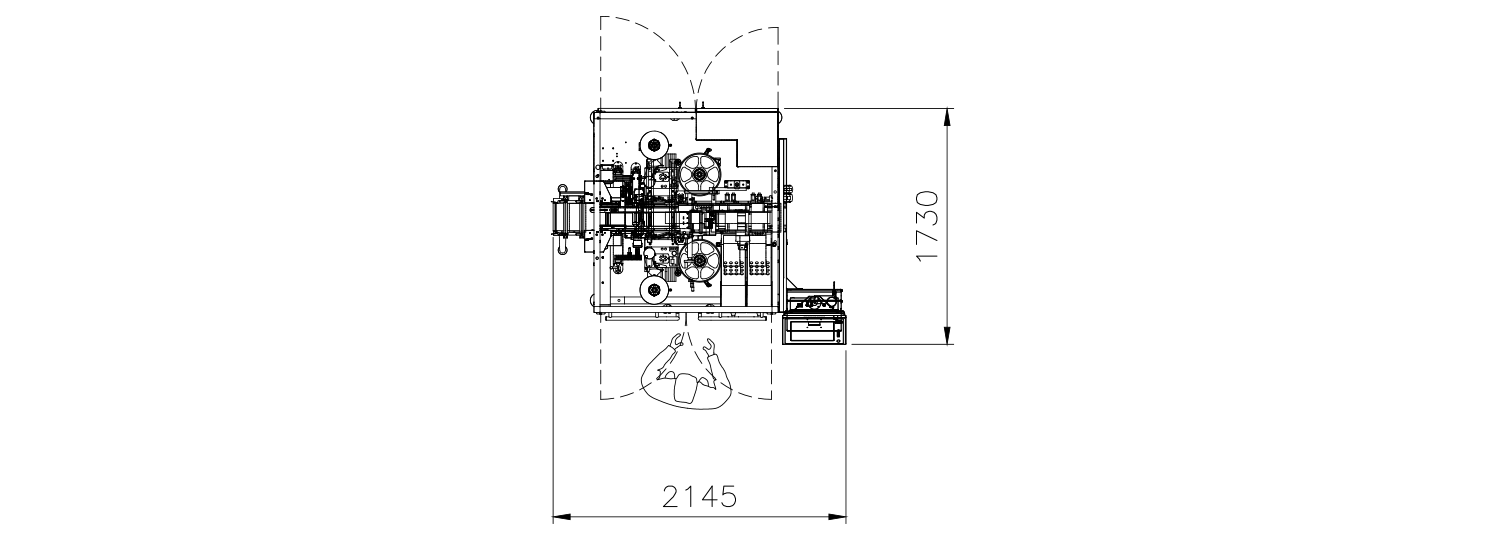

Machine Layout

DATASHEET : https://www.romaco.com/files/website/03_Products/07_Promatic/PTT-Series/04_Technical-Data/Files/Romaco_DB_Promatic_PTT-EN.pdf

Technical Data :

| PTT 250 | PTT 400 | |||

| Production speed (cartons/min.) | 250 | 400 | ||

| Length (mm) | 2,630 | |||

| Depth (mm) | 1,400 | |||

| Height (mm) | 1,970 | |||

| Carton transport height (mm) | 900 | |||

| Size range (mm) | min. | max. | min. | max. |

| A | 20 | 105 | 20 | 120 |

| B | 15 | 100 | 15 | 80 |

| C | 60 | 160 | 60 | 210 |

| *Depending on product and machine configuration | ||||